Pulsation Dampener / Suction Stabilizer: A device installed in a pipe system that dampens pressure spikes and pulsations as a result of changes in the velocity of a fluid.

Cause and Effect of Pressure Pulsations

From the law of inertia, an object in motion will stay in motion unless acted upon by an outside force. Sometimes these forces are hard, such as an egg hitting the pavement, and sometimes they are soft, like jumping onto your bed. When the force is hard or sudden, damage is more likely to take place. Fluids have the same properties. When they are in motion, they have inertia. It takes an outside force to change the direction of the fluid.

Imagine a stretch of pipe with a liquid flowing through it. On one end, a valve is suddenly closed. When the valve closes, the moving liquid suddenly needs to come to a complete stop. Since most liquids can be considered incompressible, the force against the valve is a harsh impact. Similar to an egg hitting the pavement. This sudden change in momentum applies a force against the valve. Since there is nowhere for the liquid to flow, it creates a pressure spike.

A discharge dampener is designed and installed in the pipe to help absorb this pressure spike. The dampener consists of a vessel filled with gas or compressible material. When there are sudden changes in flow, the compressible material is able to compress and expand, similar to jumping onto your bed. The video below demonstrates the effects with and without a dampener.

The pressure spikes caused by a change in flow rate can be damaging to pipes and equipment within a system. The changes in pressure cause the walls of the pipes and materials to rapidly expand and contract. Over time, these changes can develop cracks in piping and equipment walls. If the pressure spike is large enough, the resulting spike may have enough pressure to cause the pipe to explode.

By installing a pulsation dampener, the intensity of these spikes are reduced to controlled levels.A dampener should be sized and installed in all piping that may experience a harmful level of pressure spikes.

Types of Pulsation Dampeners

Pulsation dampeners can be purchased in a variety of shapes, sizes, and designs. It is important to size a pulsation dampener for a specific application. Incorrect sizing or incompatible materials may cause a danger to equipment, systems, and personnel.

Membrane Pulsation Dampener: A membrane-type dampener provides a solid separation between the pumping fluid and the compressible gas. The membrane resides within the dampener and allows for the pressure to be transferred to the gas, without any mixing of the gas into the fluid.

Bladder Pulsation Dampener: A bladder type dampener fully encloses the compressible gas within a bladder. This setup ensures there is no leakage of the gas into the pumping fluid. The pressure pulsations are transferred to the gas as the bladder expands and contracts.

Bellows Pulsation Dampener: A bellows-type dampener works the same way as a bladder type dampener. However, by using a bellows-type design, it can be made with other types of materials such as PTFE or Stainless Steel. This type of dampening system is used when pumping corrosive materials that may deteriorate more common materials.

Pressure Vessel Style: A pressure vessel dampener, sometimes referred to as a “zero maintenance” style dampener does not use any moving parts. They are only effective at very high pressures. Fluids, including water, do have some degree of compressibility. Pressure Vessel Style dampeners allow for the pressure of the fluid to be dissipated within the vessel by the small amount of compressibility within the pumping fluid. In very high-pressure applications, a pressure vessel style dampener may be the only type of dampener available. It is important to note that this style of dampener does not operate as effectively as other types of dampeners.

Flexible piping: Although it is not recommended, flexible piping or hose can act as a pulsation dampener in emergency situations. As the fluid flow changes, the flexible piping is able to “move” and allow a dampening effect on the fluid. Flexible piping still requires proper sizing to reduce pressure spikes. Improper usage may result in damage to equipment and endangerment of equipment operators.

Power Zone can select and provide dampeners for your system!

Contact us today to get started!

Causes of Pressure Pulsation in Equipment

Equipment that rapidly changes flow rates is recommended to have a pulsation dampener. Plunger pumps, for example, have a highly variable flow rate. The average flow rate of a plunger pump can be accurately predicted. However, each rotation of the crankshaft produces several changes in flow velocities.

Let’s look at a single plunger for an example.

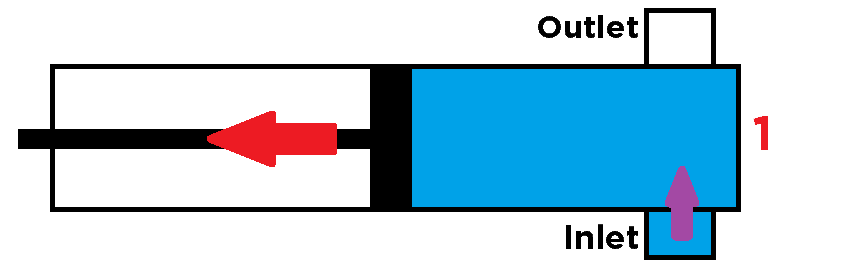

In step 1, the plunger is moving back and drawing the fluid into cavity. The fluid is flowing through the inlet.

In step 2, the plunger is stopped. It is transitioning from moving backward, to moving forwards. The fluid has stopped moving through the inlet and has come to a complete stop, resulting in a pressure spike beginning at the inlet which then travels through the suction piping. The resulting change in the fluid’s momentum is a change from kinetic energy in the form of linear velocity, to potential energy in the form of pressure.

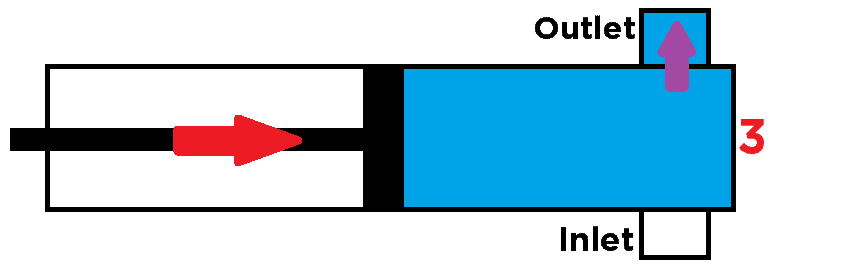

In step 3, the plunger has begun to move forward. As fluid begins moving through the outlet. The stationary fluid of the outlet is suddenly required to move as well. A pressure spike is created in the discharge, beginning at the outlet, and then carried through the discharge piping.

In step 4, the plunger has again come to a complete stop. Fluid is no longer flowing through either port. As it begins to move back, fluid will suddenly need to begin moving through the inlet.

When a plunger pump is running slowly, these pressure spikes can be ignored. In most cases, they will not produce enough of a spike to create damage. When the pump is running at full speed, this full cycle is taking place many times per second. The pressure spikes caused by these sudden changes will likely need a pulsation dampener.

The image above shows the visible pulsations created by a reciprocating quintuplex pump. Using flexible hoses on the inlet and outlet, the pressure fluctuations through the hose can easily be seen. Since steel piping is more rigid, it may be more difficult to visually see pressure vibrations before damage to piping and the surrounding systems takes place. It is important to correctly determine if a dampener is needed and to correctly install the required size before operating the pump system.

It is important to note that pressure pulsations are not a function of pressure. The operational pressures of a system have very little effect on the resulting pressure pulsations. Both suction and discharge sides of a reciprocating pump are susceptible to pulsations and resulting damage. Both the suction and discharge dampeners operate independently of each other. Proper sizing and installation of both suction and discharge dampeners are required for proper protection of pumping equipment and systems.

Power Zone does not provide warranty to any pump that does not have adequate dampening systems installed.